As the saying goes: To get rich, build the road first!

Without convenient transportation, there is no economic development, and transportation can be said to be a necessary prerequisite for economic development.

As an important transportation facility, the road is the most important part of a city, which is related to the image of the city and the development of the city.

Good roads not only ensure smooth traffic, but also bring convenience to people's travel. They can also eliminate safety hazards on the road and have many benefits.

In order to improve the quality of road use, extend the service life of the road, and add some strength to the road surface, the fiber people have been making unremitting efforts.

Today, Xiaobian will come to know about Polypropylene Sesi, a kind of material commonly used in road construction to improve the performance of road pavement.

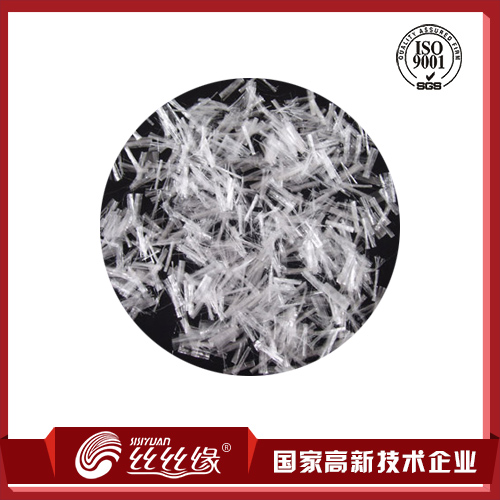

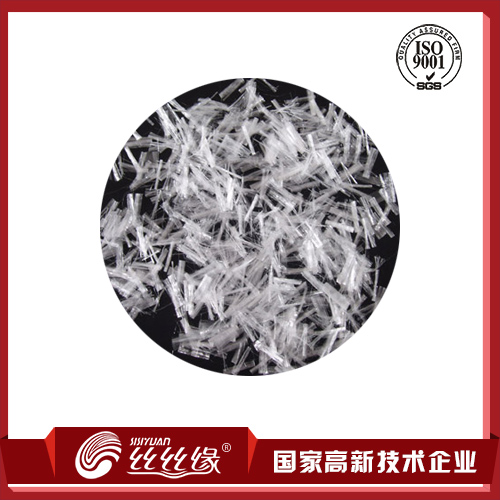

Polypropylene Sesi is made by using modified polypropylene as raw material, through extrusion, stretching, web forming, surface modification, and short cutting.

The Polypropylene Sesi is formed into a mesh shape. During the mixing process of the concrete, the reticular fiber is squashed and squashed into a single hook-shaped monofilament and a multi-directional distribution is involved, thereby reinforcing the bonding of the fiber and the concrete. force.

A large number of Polypropylene Sesiare distributed in a three-dimensional state in concrete, providing a mesh support function, which utilizes polypropylene fibers with high strength, acid resistance, alkali resistance, antimicrobial resistance, wet and dry strength, etc., and fundamentally changes the concrete. The anti-cracking, anti-shock, anti-fatigue and anti-wear properties greatly improve the toughness and deformation ability of concrete, and the quality of concrete engineering is significantly improved. It is widely used in the manufacture of pile caps, reinforcement of river banks, concrete roads and other fields.

Advantages of Polypropylene Sesi:

1. Good chemical stability, safe and non-toxic, acid and alkali resistant, antimagnetic and rustproof;

2. The fiber has good dispersibility, Y-shaped cross section, larger than surface area, rough surface porous and strong bonding strength of cement base material, no merging, no winding, no joint;

3. Simple construction and economical reliability. There is no need to change the original concrete mortar ratio;

4. There is no limit to the minimum coverage of concrete;

5, the use is simple, directly add concrete to stir.

As a professional company engaged in the research and development of all kinds of engineering fibers, high-strength Polypropylene Sesi, high-strength double-twist polypropylene filament, and integrated line manufacturing, we have many years of experience in polypropylene fiber production, with annual sales of nearly 100 million yuan and strong strength. Professional and reliable!

Silk silk chemical fiber products have excellent quality, have passed ISO9001: 2000 international quality management system certification, awarded the "National Quality Trustworthy Enterprise" by the China Famous Brand Promotion Association, officially recognized, leading technology!

The Polypropylene Sesiproduced by silk edge has excellent performance, light weight, high strength, good elasticity, wear resistance, corrosion resistance, strong electrical insulation and warmth retention, etc. It is widely used in highways, high-speed railways, Airports, tunnels, bridges, water conservancy, hydropower, municipal, civil air defense, industrial and civil buildings.

In the construction of the road network extending in all directions, to extend the service life of the road and reduce the maintenance cost, Silk Silk specializes in the production of Polypropylene Sesito protect your travel safety!