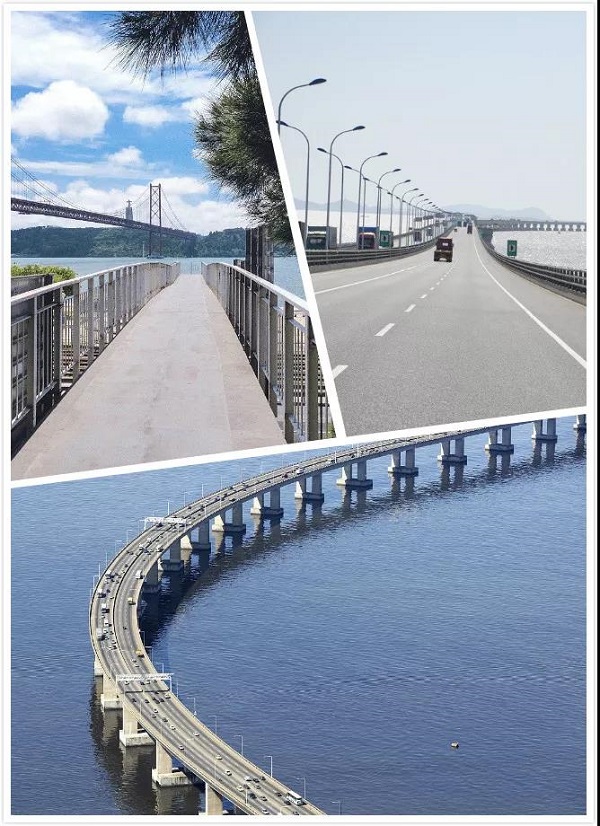

Bridges refer to buildings built for roads that span natural or artificial obstacles. They are set up on rivers and lakes to allow pedestrians to pass smoothly.

Bridges are very common in our daily life, facilitating our travel across rivers, lakes, and seas, shortening our travel time and playing an important role in our lives.

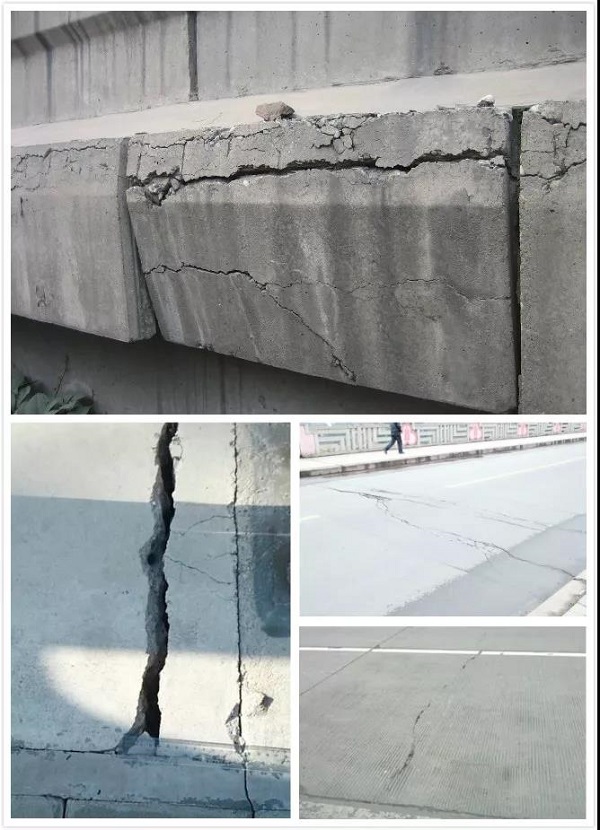

Five factors make the bridge "the most injured"

1.Overload

Overloading is the chief "killer" of damaged highway bridges. Especially when heavy-duty freight vehicles are rolled for a long time, it is very easy for the expansion joints of the bridge to be subjected to excessive force, resulting in the damage of the girder that plays a major role in bearing and easily causing the bridge to collapse.

2. Temperature

Temperature is also an important factor that causes the bridge to be susceptible to danger. If bridge expansion joints are set too long, and maintenance is not in place at a later stage, combined with rain and snow erosion, expansion joints can easily cause failure and damage to the girders.

3. Beams and holes

In particular, some of the old bridges used are mostly hollow beams, which are prone to pits and, in addition to rolling carts, can easily cause road collapse.

4. Deck empty slot

If a vehicle malfunctions while driving, the engine oil used by the driver to repair the vehicle will cause corrosion to the road surface and lead to empty slots. If the empty slot has a long time, it will have a greater impact on the bridge.

5. Rainwater

In summer, there is a lot of rainwater. In particular, there were flood bridges on some rural roads in the past. If the rainwater is too large, it will easily impact the bridge.

In the summer, the bridge was "injured" frequently

A variety of factors can lead to cracks and damage to the bridge. In the blink of an eye again in summer, summer is a period of high risk for bridges.

In summer, when the sun is shining, the bridge components are vulnerable, and thermal expansion occurs, which results in the deformation of the whole bridge. In addition, the destruction of other factors can easily affect the performance of the bridge and cause potential safety hazards.

How to strengthen bridge performance, reduce the frequency of cracks, and improve the overall stability and safety of the bridge?

Anti cracking with "artifacts"

Polypropylene fiber is a powerful weapon to reduce cracks in concrete decks.

Concrete added with polypropylene fiber, in the concrete mixing process, the fiber is destroyed by the kneading and friction of the concrete itself, forming a monofilament or a net structure to fully open, thereby achieving the effect of reinforcing the concrete.

Polypropylene fiber monofilament has a large fineness, a large number, simple construction, and a low manufacturing cost. Polypropylene fiber concrete not only has the characteristics of ordinary concrete, but also completely inhibit plastic shrinkage cracks, enhance impact resistance, improve toughness and ductility, corrosion resistance, wear resistance and reduce permeability, resistance to early plastic shrinkage cracks, can prevent and delay The ability of the structure to be corroded by the main tendons or steel plates.

"Silk edge" brand polypropylene fiber

“Silk Edge” brand polypropylene fiber is widely used in mortars and concretes. When the blending ratio is less than 1%, the shrinkage rate of concrete can be reduced by about 75%, effectively preventing the occurrence and development of original cracks in concrete, eliminating or reducing The number and scale of primary micro-cracks greatly improve the overall performance of mortar and concrete, and increase the supporting force and strength of concrete decks.